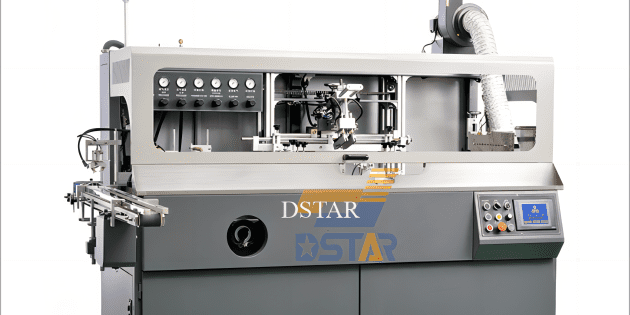

Product name: Automatic baby bottle screen printing machine screen printer for baby feeding

Model: DX-S101

Printing color1 color or multi-color

Printing size: Cylinder ¢20-100mm Height 25-300mm

Oval W25-120mm Height 25-300mm

Speed:cylinder 4,000pcs/hr ,oval 5,000pcs/hr

Voltage: AC380V 3Phase

Application: Plastic bottle, glass bottle

Printing samples

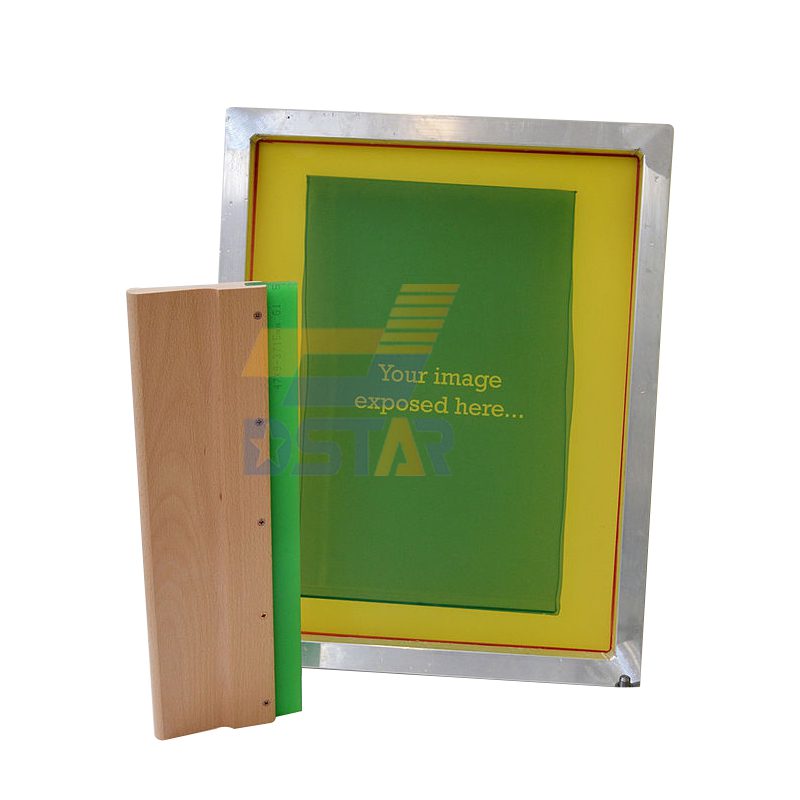

Screen printing consumables

Screen Printing Screens: Screens, also known as mesh or stencils, are stretched over frames and used to transfer the design onto the substrate. Screens are typically made of polyester or nylon mesh stretched over aluminum or wooden frames.

Various types of ink are used in screen printing, including water-based, plastisol, and solvent-based ink. The choice of ink depends on factors such as the substrate material, desired print quality, and printing method.

Squeegees are used to push ink through the screen and onto the substrate. They come in various shapes, sizes, and durometers (hardness) to accommodate different printing needs.

Machine video

Machine features

- Automatic loading&unloading: Baby bottles are automatically loaded and unloaded onto a conveyor system or fixture that moves them through the printing process.

- Registration: The bottles are aligned in a precise manner to ensure accurate printing registration. This step is crucial for ensuring that the design is printed in the correct position on each bottle.

- Flame pretreatment: Before printing, remove impurities from the bottle’s surface to keep the printing position clean, ensure the quality of the printed image, and enhance the adhesion of the ink.

- Automatic Printing: As each bottle moves through the machine, a screen or stencil with the desired design is pressed against the surface of the bottle. Ink is then forced through the screen using a squeegee, transferring the design onto the bottle.

- Curing after printing: After printing, the bottles may pass through a curing station where the ink is dried or cured using UV light or heat. This ensures the ink adheres properly to the surface of the bottle and remains durable.

Contact us

-

Automatic Pharmaceutical Glass Ampoule Bottle Screen Printing Machine

-

Wholesale Thin Pad Printing Plates Steel Pad Printing Plate 0.5mm 0.3mm

-

PPSU/PES/PP Baby Feeder Bottle Printing Plastic Bottle Screen Printing Machine

-

Why choose screen printing for bottle printing?