Product: automatic hot stamping machine for bottle caps top and sidewell

Application:bottle closure hot stamping

Model: DX-AHM

Bottle closure diameter:《100mm

Hot stamping speed: about 15-20 pcs/Min

Machine power: AC220/3KW

automatic feeding and unloading

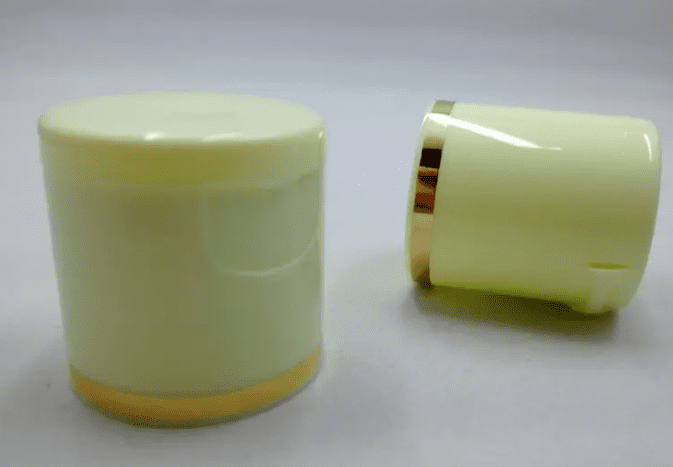

Bottle caps samples

Machine features

Automatic hot stamping machines for bottle caps are specialized equipment designed to efficiently apply foil stamping or other decorative finishes onto the surface of bottle caps.

These machines are commonly used in the packaging industry to enhance the appearance of bottle caps and create branding or decorative effects. Here are some key features and considerations for automatic hot stamping machines for bottle caps:

1. **High-speed operation**: Automatic machines are designed for high-speed production, capable of stamping a large number of bottle caps per minute.

This ensures efficient production and increased throughput.

2. **Precise positioning**: The machines are equipped with precision positioning systems to ensure accurate alignment of the bottle caps for consistent stamping results.

This is essential for maintaining the quality and aesthetics of the finished products.

3. **Customization options**: Many automatic hot stamping machines offer flexibility in terms of design customization.

They may support various foil colors, patterns, and designs, allowing manufacturers to create unique branding or decorative elements on the bottle caps.

4. **Integrated controls**: Modern machines often feature user-friendly touchscreen interfaces or control panels for easy operation and setup.

They may also offer programmable settings for adjusting parameters such as stamping temperature, pressure, and dwell time.

5. **Durability and reliability**: Automatic hot stamping machines are built to withstand the rigors of continuous operation in industrial settings.

They are constructed from durable materials and incorporate robust components to ensure long-term reliability and minimal downtime.

6. **Safety features**: Safety is a critical consideration in machine design. Automatic hot stamping machines may incorporate safety features

such as emergency stop buttons, protective guards, and interlocking systems to prevent accidents and ensure operator safety.

7. **Integration capabilities**: Some machines may offer integration capabilities with other equipment in the production line, such as bottle capping machines or inspection systems. This facilitates seamless workflow integration and streamlines the production process.

8. **Maintenance and support**: Manufacturers often provide maintenance services and technical support to ensure optimal performance and longevity of the machines.

Regular maintenance and timely support can help minimize downtime and maximize productivity.

Overall, automatic hot stamping machines for bottle caps are essential equipment for manufacturers looking to enhance the visual appeal and branding of their products.

By investing in high-quality machines that offer speed, precision, and customization options, manufacturers can efficiently produce decorated bottle caps that meet their specific requirements and market demands.