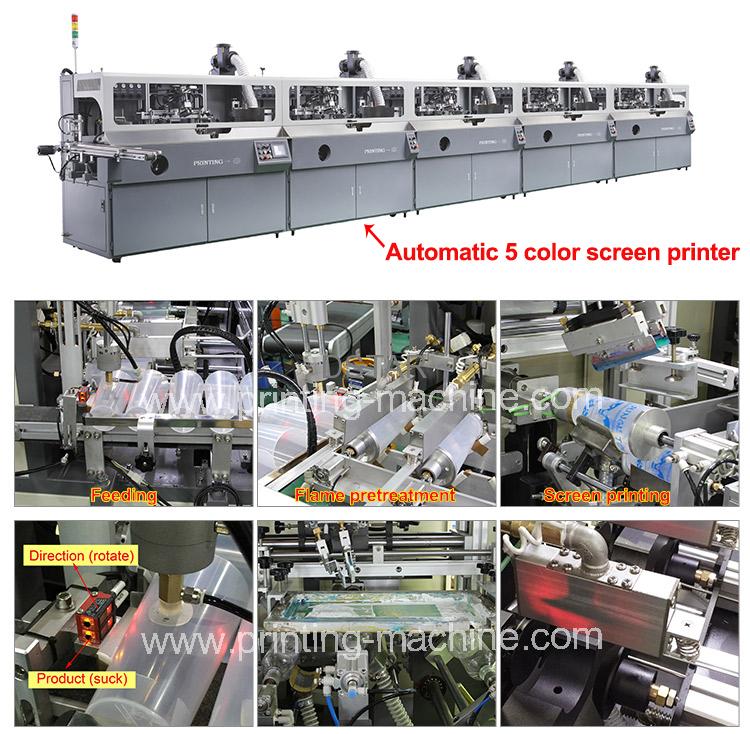

product: Fully automatic multicolor screen printing machine for glass bottles 5 color screen printer

model: DX-S101-5

printing color or multi-color

Printing size: Cylinder ¢20-100mm Height 25-300mm; Oval W25-120mm Height 25-300mm

Speed: cylinder 4,000pcs/hr ; oval 5,000pcs/hr

Voltage: AC380V 3Phase

Power:Machine(1.5KW) UV(5KW)/Unit

Air supply:0.6Mpa

Gas:0.15Mpa

Machine size: L1000*W100*H150cm

N.W:5000KGS

Machine printing processing:

Machine working:

1.Product feeding

2. Automatically pick up to machine

3. Flame pretreatment on the product surface (Such as PP/PE/HDPE material)

4. Automatic printing

5. Printing ink curing (UV curing or LED-UV curing)

6. Multi-color processing like step 4 and step 5

7. Automatic unloading

Machine features

Machine features

- automatic loading system

- automatic flame treatment

- UV curing system or LED-UV curing system

- infinitely variable speed control system

- non-printing without bottles

- automatic pre contraposition system

- widely used for printing different shapes of domestic bottles, medicine bottles, food packing containers

- the machine has with PLC system and advanced touch screen for smart operation

- the whole machine is combined with advanced motors and pneumatic parts to ensure infinitely variable speeds, automatic position matching, automatic feeding, and non-printing without the bottle

- can be used for printing oval, cylinder, and irregular shape bottles.Such as plastic, glass, metal, and so on.

- Multi-color bottle printing machines can be divided into independent single-color printing machines. For example, DX-S101-5 can be divided into 5 units of single-color printing machines.

Machine video of 5 color rotary printing machine for food can

Contact us

-

Automatic Pharmaceutical Glass Ampoule Bottle Screen Printing Machine

-

Wholesale Thin Pad Printing Plates Steel Pad Printing Plate 0.5mm 0.3mm

-

PPSU/PES/PP Baby Feeder Bottle Printing Plastic Bottle Screen Printing Machine

-

Why choose screen printing for bottle printing?