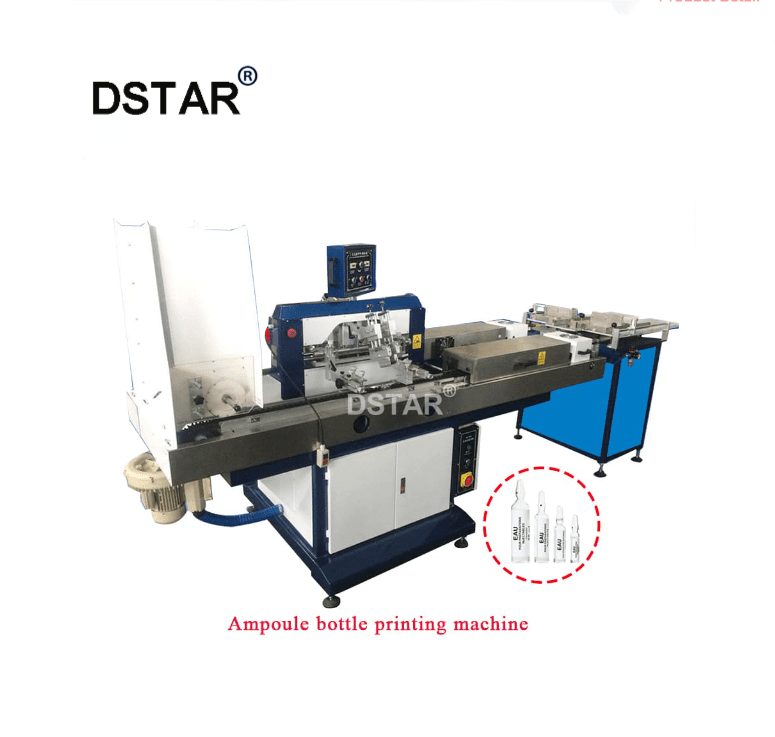

- Product: Plastic bottle cap top hot foil stamping machine with rotary workbench

- Model: DX-AHMS1

- Brand: DSTAR

- Work table size:230*230mm

- Heat panel size:150*230mm

- Speed:20times/Min

- Temperature: Max 350°C

- Power:AC220V/50HZ/1000W

- N.W:520KGS

- G.W:565KGS

- Machine size: L865*W1180*H1420mm

- Packing size: L900*W1110*H1450mm

Machine details

- Manual feeding automatic unloading: the hot stamping machine is the primary component responsible for applying heat and pressure to transfer a foil or pre-dried ink onto a substrate. It consists of a heated plate or platen, which heats the stamping die or plate to a specific temperature, and a mechanism for applying pressure to the substrate.

- Hot stamping machine for flat product printing

- Hot stamping machine with divider workbench: the divider workbench is an additional component attached to the hot stamping machine, providing a segmented or divided work surface. This workbench helps organize and separate the substrates being stamped, allowing for the efficient production of multiple items simultaneously or sequential stamping of different designs or areas on the same substrate.

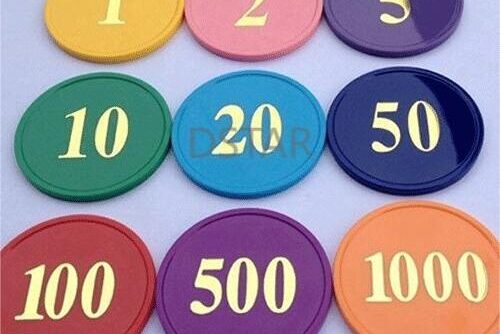

- Substrates: Substrates refer to the materials onto which the foil or ink is transferred during the hot stamping process. Common substrates include paper, cardboard, plastics, leather, and textiles, among others.

- PLC system touchscreen

- 6 stations for place products

- .Controls and Settings: The hot stamping machine typically features controls and settings for adjusting the temperature, pressure, and dwell time (the duration the stamping die is in contact with the substrate). These settings can be fine-tuned to achieve optimal stamping results based on the type of substrate and foil or ink being

Printing sample